mmayo

Member

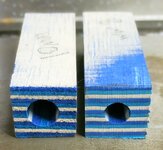

Anyone else have any issues drilling these materials? I drilled 15 acrylic acetate, four leopard wood and four inlace blanks without issue rotating five Colt 7mm bits. Each time I tried a laminated wood I got an off center exit hole. Not bad, but not centered. All other materials had centered exit holes as expected and desired. The laminated pens turned out well, but I could have had a negative impact with a larger pen kit.

If you have a method, I'm all ears, or eyes or I want to know. Thanks

If you have a method, I'm all ears, or eyes or I want to know. Thanks