VE5MDH

Member

Ladies & Gentlemen of the IAP...

Items in inventory:

MT2:

- Rikon 70-220VSR from Lee Valley (Set to 615-620 RPM for this task)

- Jacob's Chuck (Lee Valley Tools) (Tail Stock)

- 3/8" Drill Bit HSS (PSI) (Tail Stock)

- Baracuda2 4 Jaw Chuck (PeachTree in GA) (Head Stock)

- PSI C Series Pen Jaws for the Bolt Action Pen Kits (PSI) (Head Stock)

View in Gallery

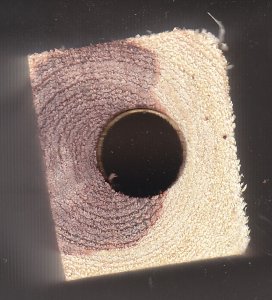

Now these tubes are not glued in the blanks yet. They are just sitting inside the blanks.

I need your honest opinion on the air gap between the tubes and the blanks.

These were drilled using the above configuration.

On one of the blanks above, I used a 23/64" bit, but the hole was too small for the brass tube to enter into the hole! So I ended up chasing a 3/8" bit through the hole. These 3/8" holes for the Bolt Action Pen Kit (PSI), just seems to be way too large or oversized holes drilled in the blanks.

It is my own opinion that it may seem that there must be some sort of wobble making the holes slightly larger than they should be. Now, I could be very wrong, and these may be drilled right down the keister! (You know... Zero Tolerance).

You spend this kind of money, and you expect that there should be NO AIR GAP down the centreline! (Am I just too much of a perfectionist?). The PSI Pen Jaws Instruction Sheet was followed to the Tee.

Please share your thoughts, observations, ideas, comments or even rants! Remember now, these blanks are not glued in.

Michael

Items in inventory:

MT2:

- Rikon 70-220VSR from Lee Valley (Set to 615-620 RPM for this task)

- Jacob's Chuck (Lee Valley Tools) (Tail Stock)

- 3/8" Drill Bit HSS (PSI) (Tail Stock)

- Baracuda2 4 Jaw Chuck (PeachTree in GA) (Head Stock)

- PSI C Series Pen Jaws for the Bolt Action Pen Kits (PSI) (Head Stock)

View in Gallery

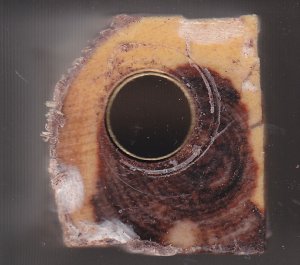

Now these tubes are not glued in the blanks yet. They are just sitting inside the blanks.

I need your honest opinion on the air gap between the tubes and the blanks.

These were drilled using the above configuration.

On one of the blanks above, I used a 23/64" bit, but the hole was too small for the brass tube to enter into the hole! So I ended up chasing a 3/8" bit through the hole. These 3/8" holes for the Bolt Action Pen Kit (PSI), just seems to be way too large or oversized holes drilled in the blanks.

It is my own opinion that it may seem that there must be some sort of wobble making the holes slightly larger than they should be. Now, I could be very wrong, and these may be drilled right down the keister! (You know... Zero Tolerance).

You spend this kind of money, and you expect that there should be NO AIR GAP down the centreline! (Am I just too much of a perfectionist?). The PSI Pen Jaws Instruction Sheet was followed to the Tee.

Please share your thoughts, observations, ideas, comments or even rants! Remember now, these blanks are not glued in.

Michael

Last edited: