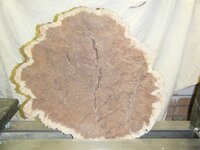

I would make the entire burl into a bowl. No trimming at all. Just sand down the edge a little to protect the hands of whoever handles the finished product. Power carve the inside and leave a good half inch of inside wood to protect the lighter wood from showing up. Be careful as you carve and follow the general outside edge to form the inside.

The more you sand the inside the prettier it will be. I usually finish with a quality clear polyurethane finish with sanding between the several coats of applied finish. Then when fully cured I polish with Carnuaba wax using buffing wheels.

I usually sand down the prickly 'spear points' and may quite often take them all the way down to a smooth edge leaving the larger natural creases alone. The spears form great burl eyes and are spectacular looking IMHO.

Just go slowly and take your time. BTW, cloth sandbags loosely filled will greatly facilitate the carving. Carve the inside prior to removing the 'spears' as they will hold onto the cloth bag material. I use money bags from the bank as sand bags. A heavy duty plastic bag inside the cloth bag holds the sand just great. Put the plastic bag inside the cloth bag, fill them with sand, fold over the top several inches, put a piece of tape over the fold and stitch up the cloth top and you are set to go to town.

Have fun and keep your eyes open for the treasure inside the burl when you apply the finish.