Originally posted by Fred in NC

<br />BigRob: An indexing plate is the same as a dividing plate. It is basically a round plate with a bunch of holes drilled around it at precision distances. The plate I furnish has 24 holes at 15 degrees. It fits the Jet Mini and any other lathe with a 1" spindle. I also have some plates in stock that will fit lathes with 3/4" spindle.

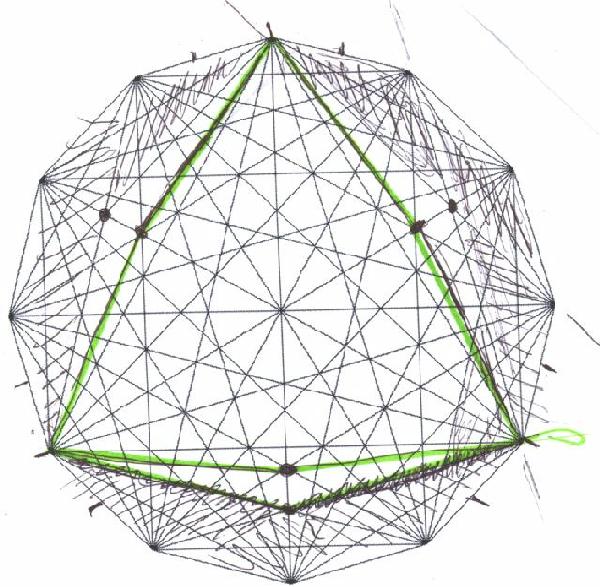

<b>Image Insert:</b><br />

<br />

The plate is put on the spindle with a washer and nut. The indexing arm pivots on a piece similar to a banjo. The whole setup can be put on the lathe easily and quickly. The pen barrels are mounted on a regular mandrel. You also can do flutes and drill holes with this setup.

<b>Image Insert:</b><br />

<br />