Steven Baxter

Member

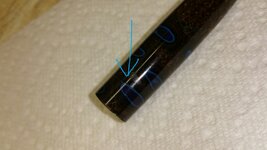

Hello all! I recently turned a banksia pod cast with alumilite and finished with CA glue. I had to disassemble the pen half way through the assembly process. I used a punch to knock the tip out. It was very tight. I ended up cracking it. One crack half way around the tube and another about 4mm long above that.

I really would like to salvage this pen. There is just so much time, effort, and resources into it. I would not feel comfortable selling it but could at least use it myself or as an example of my work.

The crack I'm sure goes down to the brass and is not just the finish. My thoughts were to sand down the finish. Fill with thin CA then sand and re finish.

Any thoughts?

I really would like to salvage this pen. There is just so much time, effort, and resources into it. I would not feel comfortable selling it but could at least use it myself or as an example of my work.

The crack I'm sure goes down to the brass and is not just the finish. My thoughts were to sand down the finish. Fill with thin CA then sand and re finish.

Any thoughts?

Attachments

Last edited: