skeenum

Member

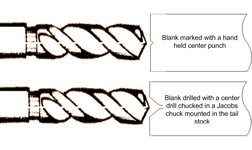

I have read where several of you use a centering bit to start holes in your blanks. What is the advantage to using a centering bit versus just using the brad point/other regular bits to center and bore the hole all the way through the blank?

How deep do you bore when boring with a centering bit? Do you under-size the hole made with the centering bit and then ream the hole with a regular bit to complete the through hole?

How much more accurate is this method?

Thank you center bit users for any information you might provide to me.

Thanks,

How deep do you bore when boring with a centering bit? Do you under-size the hole made with the centering bit and then ream the hole with a regular bit to complete the through hole?

How much more accurate is this method?

Thank you center bit users for any information you might provide to me.

Thanks,