Hey all,

I have noticed that recently I have been having an issue with my pens.

When I turn a pen my "cap" barrel is on the left of my mandrel with the clip side farthest left and the "base" barrel is on the right side of my mandrel with the nib side farthest right.

I use a mandrel saver and not a live center as well.

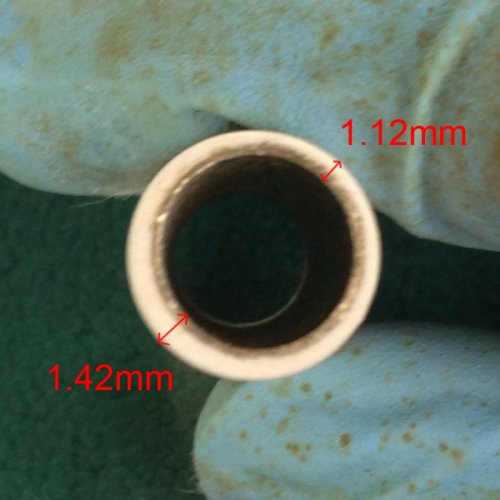

I have noticed that the section that the Nib gets pushed into is continuously off center.

View in Gallery

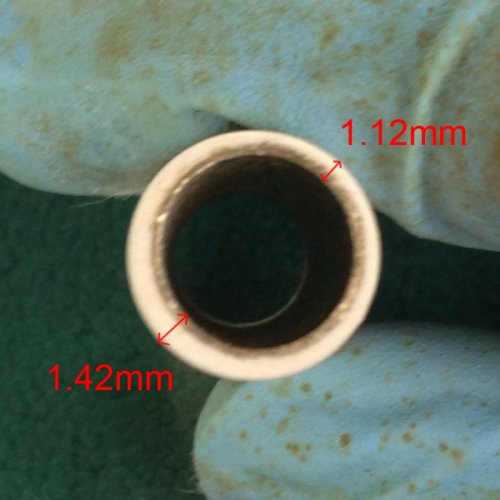

While at the same time the other side of the same barrel is spot on

View in Gallery

Now this seems to be happening on every pen, no matter the kit type, so I do not believe its an issue with the bushing being off center.

To be sure I put a caliper on the bushing I was using that produced this blank and it was pretty close to round (off by */- .03mm which I assume is well within tolerances.)

I am going to make my next pen with only using one barrel at a time and push the the mandrel saver all the way up to see if the issue is my mandrel getting out of round on the far end.

Being able to cut both barrels at once is a time saver but not having to remake a barrel is an even bigger one.

Any ideas will be welcomed.

Thanks

Jay

Tampa, FL

I have noticed that recently I have been having an issue with my pens.

When I turn a pen my "cap" barrel is on the left of my mandrel with the clip side farthest left and the "base" barrel is on the right side of my mandrel with the nib side farthest right.

I use a mandrel saver and not a live center as well.

I have noticed that the section that the Nib gets pushed into is continuously off center.

View in Gallery

While at the same time the other side of the same barrel is spot on

View in Gallery

Now this seems to be happening on every pen, no matter the kit type, so I do not believe its an issue with the bushing being off center.

To be sure I put a caliper on the bushing I was using that produced this blank and it was pretty close to round (off by */- .03mm which I assume is well within tolerances.)

I am going to make my next pen with only using one barrel at a time and push the the mandrel saver all the way up to see if the issue is my mandrel getting out of round on the far end.

Being able to cut both barrels at once is a time saver but not having to remake a barrel is an even bigger one.

Any ideas will be welcomed.

Thanks

Jay

Tampa, FL

Last edited: