KKingery

Member

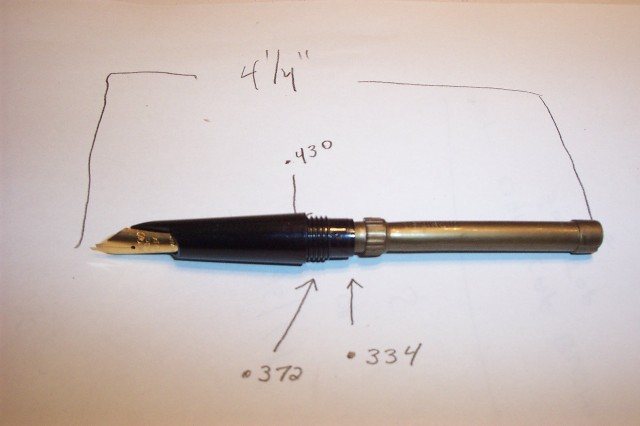

Hey all, I got a new request from one of my wifes co-workers today. He does that fancy caligraphy writing, and uses several of these special tips and ink cartridges. He wants to know if I can make him barrels, that these can screw up into. This is a pic of the tip & cartridge, with some basic dimensions that I took.

I turned a rough first attempt tonight, with the expected "first attempt" results. I used a piece of Teak, bored 4-1/2 inches through, using an "S" bit. I then inserted the 1st & 4th bushings from a cigar set (great fit) as he does'nt want tubes inserted in these. After turning, I tapped out for the threads, and got a decent fit.

My concern: with no tubes, what would you recommend for "strengthing" the barrels? The man prefers no tubes in these as they need to be light as a feather for this type of writing. I was thinking of a few coats of CA inside the barrels, and using the BLO/CA finish outside.

Any ideas would be greatly appreciated.

Here are 2 prototypes I came up with. They are made from Poplar and Cocobolo. The first pic is Poplar - made to 4 inches in length.

This pic is made from Cocobolo, to a shorter length of 3 inches.

And finally, all 3 pieces together. They were both made with no tubes, drilled using an "S" bit, and turned to a cigar end size. BLO/CA finish on both, and re-enforced with CA inside.

I turned a rough first attempt tonight, with the expected "first attempt" results. I used a piece of Teak, bored 4-1/2 inches through, using an "S" bit. I then inserted the 1st & 4th bushings from a cigar set (great fit) as he does'nt want tubes inserted in these. After turning, I tapped out for the threads, and got a decent fit.

My concern: with no tubes, what would you recommend for "strengthing" the barrels? The man prefers no tubes in these as they need to be light as a feather for this type of writing. I was thinking of a few coats of CA inside the barrels, and using the BLO/CA finish outside.

Any ideas would be greatly appreciated.

Here are 2 prototypes I came up with. They are made from Poplar and Cocobolo. The first pic is Poplar - made to 4 inches in length.

This pic is made from Cocobolo, to a shorter length of 3 inches.

And finally, all 3 pieces together. They were both made with no tubes, drilled using an "S" bit, and turned to a cigar end size. BLO/CA finish on both, and re-enforced with CA inside.