RedBeard

Member

Typically when I glue a barrel into a blank I either us Gorilla Glue or a medium CA and for the most part these have worked well for me. Now I am faced with the task of securing brass to brass and I'm a bit perplexed.

The way I see it I have two real viable options....epoxy or GG. I'm not 100% sold on the Gorilla Glue for this even though I have used it in the past for this exact purpose. I did have one failure but that was more or less my fault.

I have never used epoxy for a metal on metal bond and I guess I'm interested in hearing from other that have used it more than I. I have asked this question to Loctite and their response was to use their Marine Epoxy. The only issue I can see with that is, based on the description, it seems to be more on the brittle side. I'm not sure how it will deal with any sort of sheering force.

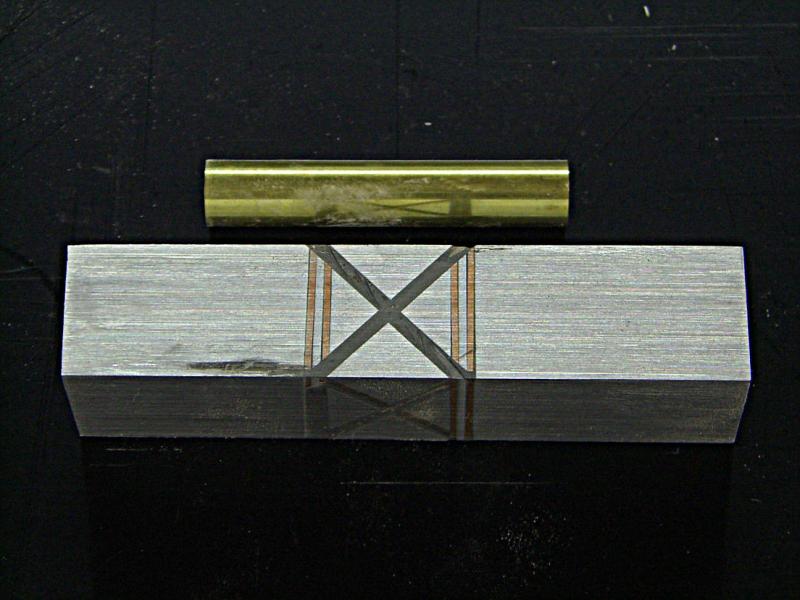

Before it's mentioned I will say that I am not interested in soldering this at all. Essentially I am bonding an outer barrel to an inner barrel with the outer being the "show" section of the pen. I have welded/braised/sweated more pipe and tube than I really care to recall and for one I don't trust soft solder to hold up.

I am leaning more towards using an epoxy (unless there are other ideas) but is here any certain type that would be better suited than another?

The way I see it I have two real viable options....epoxy or GG. I'm not 100% sold on the Gorilla Glue for this even though I have used it in the past for this exact purpose. I did have one failure but that was more or less my fault.

I have never used epoxy for a metal on metal bond and I guess I'm interested in hearing from other that have used it more than I. I have asked this question to Loctite and their response was to use their Marine Epoxy. The only issue I can see with that is, based on the description, it seems to be more on the brittle side. I'm not sure how it will deal with any sort of sheering force.

Before it's mentioned I will say that I am not interested in soldering this at all. Essentially I am bonding an outer barrel to an inner barrel with the outer being the "show" section of the pen. I have welded/braised/sweated more pipe and tube than I really care to recall and for one I don't trust soft solder to hold up.

I am leaning more towards using an epoxy (unless there are other ideas) but is here any certain type that would be better suited than another?