Marc Phillips

Member

Lemme say right off I sure appreciate all the information sharing y'all do... it really helps more than I can say!

OK... before I take the plunge and throw my mandrels away, I want to try and summarize all of this to make sure my widdle bwain has absorbed all of this correctly....

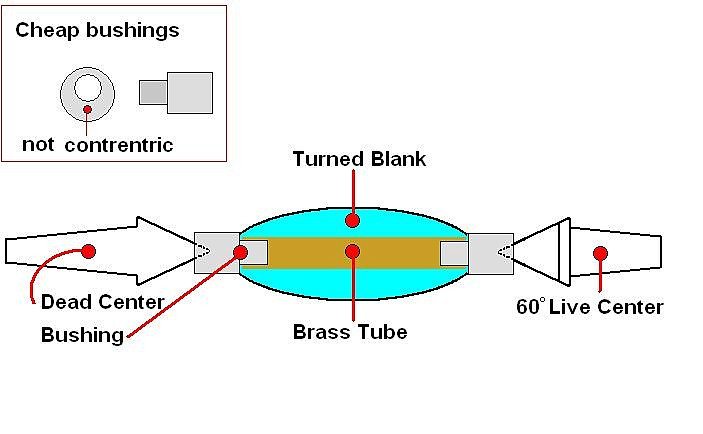

You use the bushings inserted into the blank and then mount the whole thing in between the centers... and turn each blank (upper and lower barrels) individually.

You then remove the blank, remove the bushings and remount the blank between centers to finish.

<h3>Advantages</h3>

Eliminates mandrel wobble

1. Using a CA finish, no more stuck bushings and chipping when removing stuck bushings

2. Shorter distance between centers = more stability, less wobble

3. Sanding without bushings eliminates bushing dust contaminating lighter colored woods and also bushing shrinkage [ ]

]

<h3>Questions</h3>

1. Can homemade bushings be used? ... Corian, or whatever?

2. Any problems with rounding over the ends when sanding without a bushing supporting the end of the blank?

3. Does the blank self center easily or do you have fuss with it to get it spinning smoothly?

4. For those that buff their blanks (like me) do you mount the blanks on a mandrel to hold them for buffing?

Is the drawing I did accurate.... sorta?

Thanks again for your patience... and sorry for yet another dead center post... I have read the posts about using a dead center, and I would sure love to get rid of the out-of-round pen problem...

OK... before I take the plunge and throw my mandrels away, I want to try and summarize all of this to make sure my widdle bwain has absorbed all of this correctly....

You use the bushings inserted into the blank and then mount the whole thing in between the centers... and turn each blank (upper and lower barrels) individually.

You then remove the blank, remove the bushings and remount the blank between centers to finish.

<h3>Advantages</h3>

Eliminates mandrel wobble

1. Using a CA finish, no more stuck bushings and chipping when removing stuck bushings

2. Shorter distance between centers = more stability, less wobble

3. Sanding without bushings eliminates bushing dust contaminating lighter colored woods and also bushing shrinkage [

<h3>Questions</h3>

1. Can homemade bushings be used? ... Corian, or whatever?

2. Any problems with rounding over the ends when sanding without a bushing supporting the end of the blank?

3. Does the blank self center easily or do you have fuss with it to get it spinning smoothly?

4. For those that buff their blanks (like me) do you mount the blanks on a mandrel to hold them for buffing?

Is the drawing I did accurate.... sorta?

Thanks again for your patience... and sorry for yet another dead center post... I have read the posts about using a dead center, and I would sure love to get rid of the out-of-round pen problem...