You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum Pens

- Thread starter gspalding

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

johnnycnc

Member

George,

yes, solid aluminum to start. You can drill a tube hole and glue

tubes in or if you get just the right size hole you can just drill

and press the fittings in.

If you go to my website, http://penturnersproducts.com/

at the bottom of the home page, there is a link to

INSTRUCTIONS, and there is a "how to turn and finish aluminum pens"

link there to a document I wrote up.

I use to offer the blanks already cut to length and drilled just right,

and may again if there's any interest.

Hope this helps get you started!

yes, solid aluminum to start. You can drill a tube hole and glue

tubes in or if you get just the right size hole you can just drill

and press the fittings in.

If you go to my website, http://penturnersproducts.com/

at the bottom of the home page, there is a link to

INSTRUCTIONS, and there is a "how to turn and finish aluminum pens"

link there to a document I wrote up.

I use to offer the blanks already cut to length and drilled just right,

and may again if there's any interest.

Hope this helps get you started!

Stick Rounder

Member

its_virgil

Member

Not from Home Depot or Lowes. You need to use (from my experience) either 6061 or 7075 aluminum rods. They are available from industrial supply houses like Enco , MSC Direct or McMaster Carr. I get it from a local machine shop from the barrel of cutoffs that go to the scrap yard. It only cost me a couple of pens and I can go by and get pieces to make the pens. There is a yahoo group for aluminum pens: http://groups.yahoo.com/group/aluminumpen

Do a good turn daily!

Don

Do a good turn daily!

Don

Thanks. Where do I find the aluminum?

George

Ligget

Member

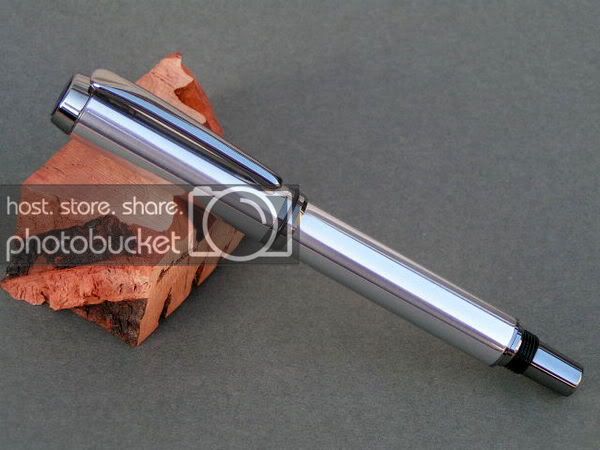

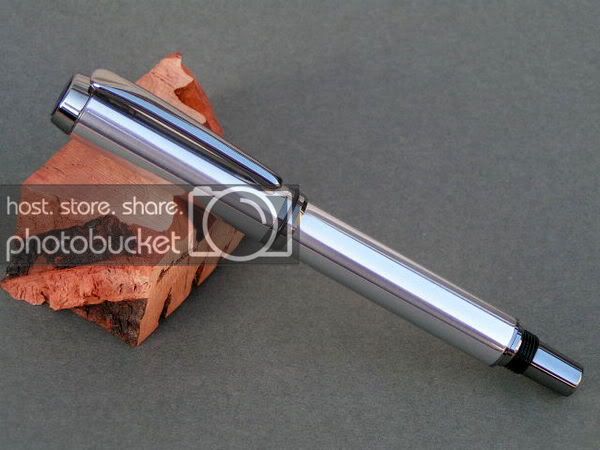

This Baron was made with blanks bought from Johnnycnc, I used a round nose scraper which I found was best for removing the most aluminium.

jttheclockman

Member

Mark

Very nicely done. I want to try my hand at the metal pen. What tools are you using??? What speed do you turn metal at??? What type finish are you putting on them??? Thanks for the help.

PS--- Can you have a metal pen lasered???

Very nicely done. I want to try my hand at the metal pen. What tools are you using??? What speed do you turn metal at??? What type finish are you putting on them??? Thanks for the help.

PS--- Can you have a metal pen lasered???

JBeck

Member

Mark, that's a beautiful pen!! What did you finish it with?

John

John

Russianwolf

Member

johnnycnc

Member

George,

I can fix you up, I have yards of it.:biggrin:

Just pm me with what you want;need to know what kit also.

*raw cut blanks,you do all drilling and squaring.

*drilled for tubes,ends squared

*predrilled directly for fittings (no tubes), ends squared

or, any combination of the above!

I'd be glad to set you up.

I can fix you up, I have yards of it.:biggrin:

Just pm me with what you want;need to know what kit also.

*raw cut blanks,you do all drilling and squaring.

*drilled for tubes,ends squared

*predrilled directly for fittings (no tubes), ends squared

or, any combination of the above!

I'd be glad to set you up.

Thanks. Where do I find the aluminum?

George

BLLEHMAN

Member

Mark, WOW thats nice.

John, there is interest from me regarding aluminum blanks

John, there is interest from me regarding aluminum blanks

rjwolfe3

Member

Me, too.

ldb2000

Member

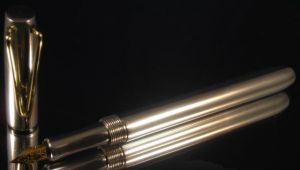

I have the Honor of the featured pen this month and it's an Aluminum and brass kitless slimline .

Here's another 2 Aluminum pens , with some brass thrown in for good measure . I use solid Aluminum bar stock I get from www.speedymetals.com

Aluminum and brass are very easily turned on a wood lathe (I use my Jet 1014vsi) . It requires sharp tools , carbide tools work better because you don't have to sharpen as often but HSS tools will work fine . Keep the rest close to the work and a tight grip on your tools and it turns like a dream .

It's best to use type T6061 which is a very machinable type of aluminum .

Here's another 2 Aluminum pens , with some brass thrown in for good measure . I use solid Aluminum bar stock I get from www.speedymetals.com

Aluminum and brass are very easily turned on a wood lathe (I use my Jet 1014vsi) . It requires sharp tools , carbide tools work better because you don't have to sharpen as often but HSS tools will work fine . Keep the rest close to the work and a tight grip on your tools and it turns like a dream .

It's best to use type T6061 which is a very machinable type of aluminum .

Blind_Squirrel

Member

It depends on what type of pen you are looking to make. I made this one on a metal lathe. It started out as a piece of 1/2" bar stock. It has a slim line transmission in it.

Ligget

Member

Great pens can be made with what tools we normally use on wood, I like the round nose scraper, turning approx 1500rpm. I finished with wet sanding from 240 grit up to 500 the micromesh from 1500 through to 12000, aluminium polish after that.

Would be easier using buffing wheels, will try this with the next aluminium pen I do!

Would be easier using buffing wheels, will try this with the next aluminium pen I do!

jttheclockman

Member

Mark

I am glad you chimed in. I love your pen. What were some of the obstacles you found making that pen??? How did you overcome them???

When you all are making metal pens, do you use the brass tube or do you just drill the blank to the right size and go from there??? What is the advantage either way??? If you use the tubes what glue are you using???

When finishing are you looking for a mirror finish or are you after a satin finish??? How hard is it to get the swirl marks out??? I assume when sanding you are using something different than micromesh because of the blackness??? Does anyone powdercoat their metal pens???

I am glad you chimed in. I love your pen. What were some of the obstacles you found making that pen??? How did you overcome them???

When you all are making metal pens, do you use the brass tube or do you just drill the blank to the right size and go from there??? What is the advantage either way??? If you use the tubes what glue are you using???

When finishing are you looking for a mirror finish or are you after a satin finish??? How hard is it to get the swirl marks out??? I assume when sanding you are using something different than micromesh because of the blackness??? Does anyone powdercoat their metal pens???

titan2

Member

George,

I can fix you up, I have yards of it.:biggrin:

Just pm me with what you want;need to know what kit also.

*raw cut blanks,you do all drilling and squaring.

*drilled for tubes,ends squared

*predrilled directly for fittings (no tubes), ends squared

or, any combination of the above!

I'd be glad to set you up.

Johnny,

What would it cost me for: *predrilled directly for fittings (no tubes), ends squared in a slimline kit?

TIA

Barney

NewLondon88

Local Chapter Leader

I've been messing around with aluminum and brass on the lathe

and it's great. I bought some 6061 and something else, I forget

the number, but it was a lightning rod. Turned fine with wood turning

chisels. Heats up a LOT. Sands well and will polish up to a mirror

finish, but I cut it back because it doesn't quite match the chrome

kit I used it on and when they're too close but don't match it looks

awkward. But with a satin finish and chrome, it looked deliberate.

I've been wondering about some sort of finish, though. Maybe a

lacquer for metal, just haven't gotten around to it. The aluminum

is soft and marks up easily.

and it's great. I bought some 6061 and something else, I forget

the number, but it was a lightning rod. Turned fine with wood turning

chisels. Heats up a LOT. Sands well and will polish up to a mirror

finish, but I cut it back because it doesn't quite match the chrome

kit I used it on and when they're too close but don't match it looks

awkward. But with a satin finish and chrome, it looked deliberate.

I've been wondering about some sort of finish, though. Maybe a

lacquer for metal, just haven't gotten around to it. The aluminum

is soft and marks up easily.

Attachments

Last edited:

jttheclockman

Member

Charlie

I like the brass cigar. Where did you get the brass??? Do you use tubes or do you drill exactly for the kit??? Is there a number also for the brass that I should look for??? Does one turn harder than the other??? Thanks for the reply. Boy this could be a whole other avenue of pen turning to try. Man this stuff is fun.

I like the brass cigar. Where did you get the brass??? Do you use tubes or do you drill exactly for the kit??? Is there a number also for the brass that I should look for??? Does one turn harder than the other??? Thanks for the reply. Boy this could be a whole other avenue of pen turning to try. Man this stuff is fun.

Last edited:

NewLondon88

Local Chapter Leader

FWIW .. I wouldn't do the brass cigar again.. it weighs a quarter of a pound.

I think it was 501 brass? Not sure, I know nothing about this stuff. But

it was a 3 ft rod, 3/8 inch. I turned that one on a Taig. I drilled it out on

the Jet mini (wood lathe) with a jacobs chuck holding the drill bit and the

brass rod chucked in a Barracuda with pin jaws. Drilled it out to just under

the kit size, then fine tuned it when I fit the parts.

Definitely use cutting fluid.

I thought I'd make a great looking copper pen, but the copper didn't like

being turned, I guess. I got it drilled out, but I'm still not sure how. It doesn't

turn well, it binds. It'll stop your lathe on a dime.

.. and yes .. it's all fun!

I think it was 501 brass? Not sure, I know nothing about this stuff. But

it was a 3 ft rod, 3/8 inch. I turned that one on a Taig. I drilled it out on

the Jet mini (wood lathe) with a jacobs chuck holding the drill bit and the

brass rod chucked in a Barracuda with pin jaws. Drilled it out to just under

the kit size, then fine tuned it when I fit the parts.

Definitely use cutting fluid.

I thought I'd make a great looking copper pen, but the copper didn't like

being turned, I guess. I got it drilled out, but I'm still not sure how. It doesn't

turn well, it binds. It'll stop your lathe on a dime.

.. and yes .. it's all fun!

johnnycnc

Member

Johnny,

What would it cost me for: *predrilled directly for fittings (no tubes), ends squared in a slimline kit?

TIA

Barney

Pm sent, Thanks!