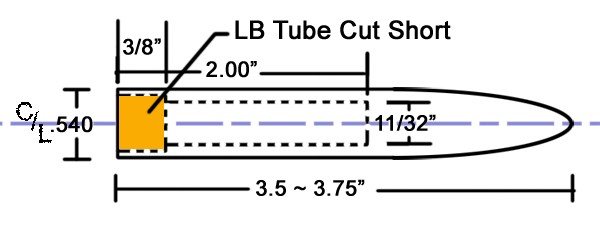

I am planning to do a solid body Ligero FP... I have an idea on paper (see below)... The concept is to use a shortened lower barrel tube and then drill the rest of the lower barrel smaller in diameter so I have clearance for the ink cartridge.. I don't intend to make this one deep enough for the converter.. that will come later if this works.. I am also increasing the length of the pen by .5to.75".. most likely .5

Well the question is..

Am I on the right track... and if not where am I going wrong..

The cap will get a similar treatment instead of the plastic top and the trim ring will disappear and only a very short piece of the plastic overlay will remain.

Just so you don't go reaching for your calculators 11/32"=.343"

Well the question is..

Am I on the right track... and if not where am I going wrong..

The cap will get a similar treatment instead of the plastic top and the trim ring will disappear and only a very short piece of the plastic overlay will remain.

Just so you don't go reaching for your calculators 11/32"=.343"