greenmtnguy

Local Chapter Leader

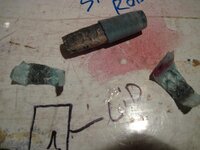

I think people are getting the impression that our 3D blanks take days to complete. Here is an actual time frame on a test blank I did today.

totally painted and ready for Ca was 12 min. Paint the tube a solid color and dry. Using my special tool, tap the paint to almost dry on a fingertip and apply with the lathe running at a fairly high speed lightly touching the blank.

Another tool for fine detail. Tap color dry and touch lightly to spinning blank.

Complete and dry at 12 min.

I applied CA at 810 rpm. I had 3 coats on and dry at 18 min and that is geting CA and paper towels ready too.

CA was done ar 38 min.

Finished at 1810 rpm on a Rikon without variable speed.

50 min later I am done. If I was going to keep this blank, I am sure I would have taken some more time, but the band on the end of the blank is not on the finished product. Had to adjust the laser to a different style of blank.

totally painted and ready for Ca was 12 min. Paint the tube a solid color and dry. Using my special tool, tap the paint to almost dry on a fingertip and apply with the lathe running at a fairly high speed lightly touching the blank.

Another tool for fine detail. Tap color dry and touch lightly to spinning blank.

Complete and dry at 12 min.

I applied CA at 810 rpm. I had 3 coats on and dry at 18 min and that is geting CA and paper towels ready too.

CA was done ar 38 min.

Finished at 1810 rpm on a Rikon without variable speed.

50 min later I am done. If I was going to keep this blank, I am sure I would have taken some more time, but the band on the end of the blank is not on the finished product. Had to adjust the laser to a different style of blank.