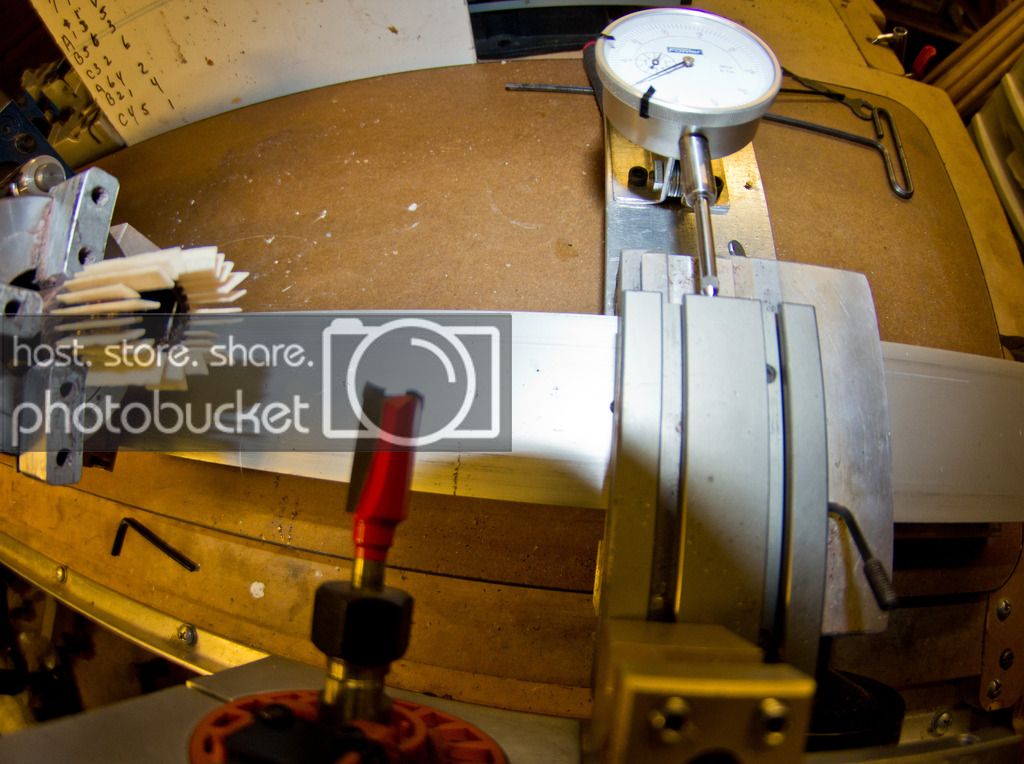

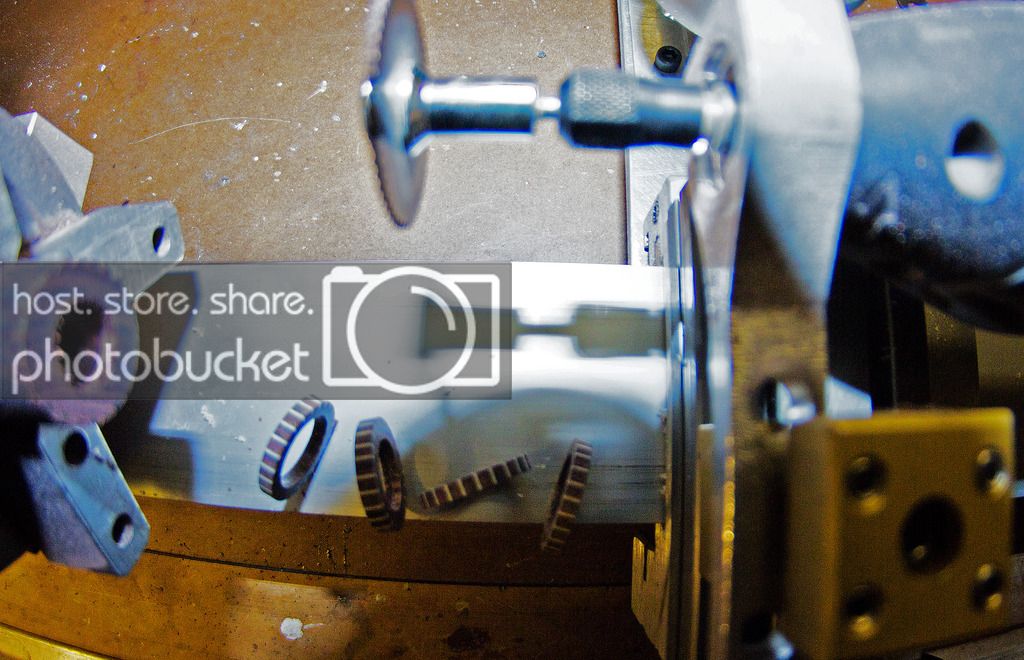

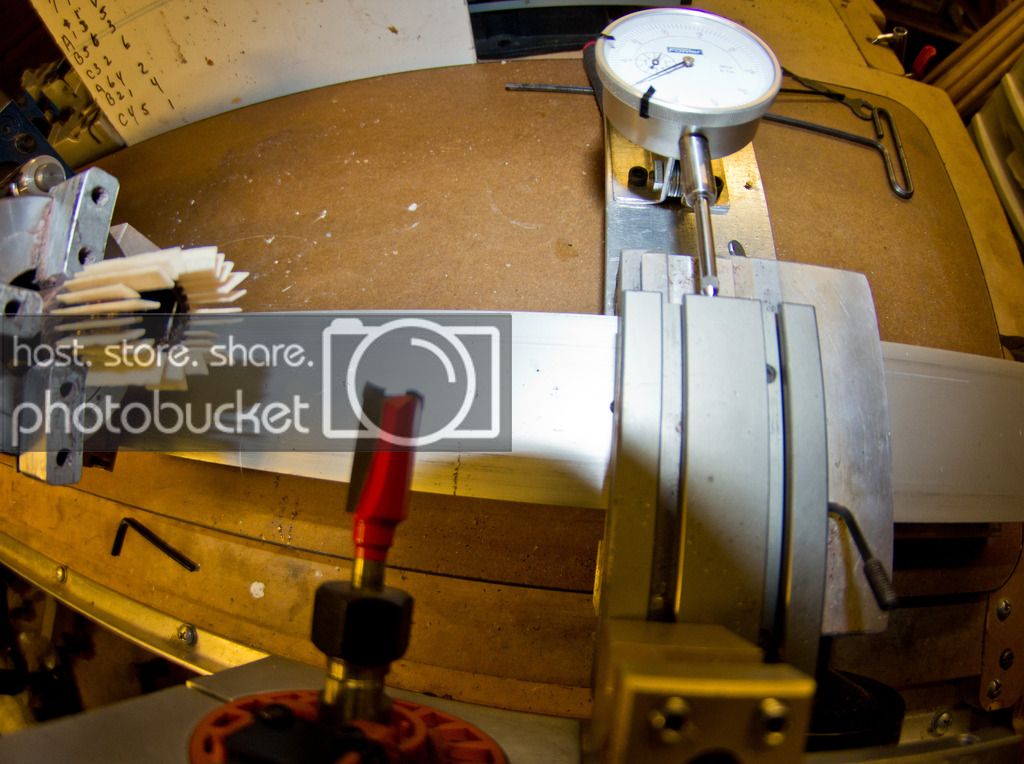

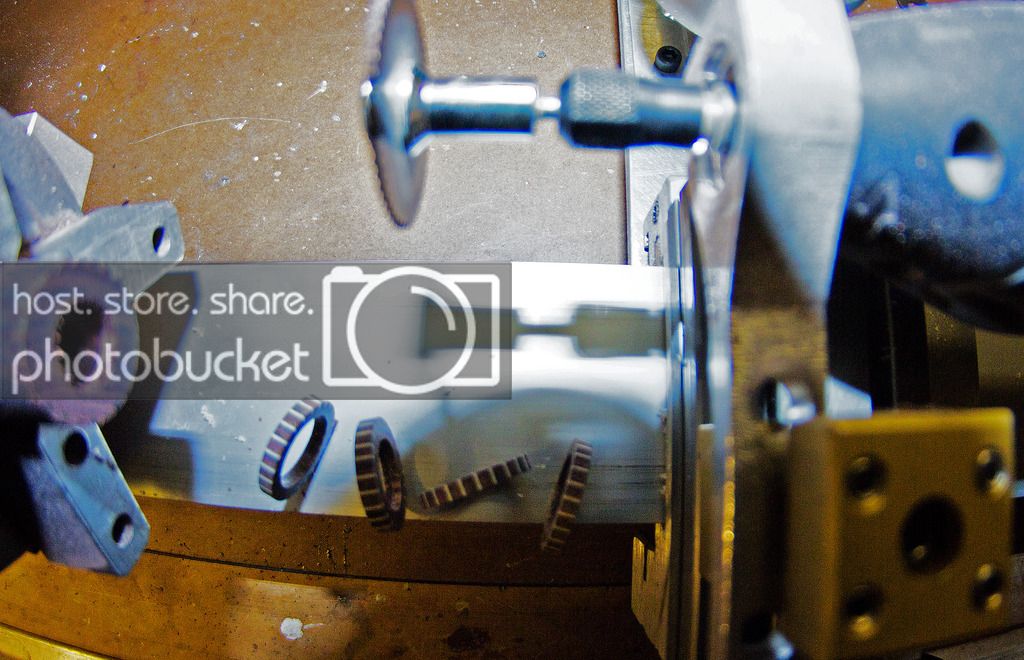

24 position indexer, 1.250 od saw blade 0.030 width mounted on a dremel.

0.030 to 0.035 white veneers .

Kingwood dowel cut 24 times like a spline on a axel or a input shaft on a manual transmission .

Cut 24 slots, and check every slot with a strip of veneer, then super glue in 5 or 6 pieces of veneer a spray with a activator until all 24 slots have veneers glued in them.

Then cut into washers or rings .

Sorry I don't make many pens, I do enjoy wood working but I make very few pens.

I thought I would share this with you.

You must have a engine style lathe, a indexer and a live tool post cutter that you can cut a 0.030 width of a slot.

Finished product is a billiards chalk holder.

This is made out of Elk antler and Gabon Ebony.

hope this gives a few of you guys some ideas

0.030 to 0.035 white veneers .

Kingwood dowel cut 24 times like a spline on a axel or a input shaft on a manual transmission .

Cut 24 slots, and check every slot with a strip of veneer, then super glue in 5 or 6 pieces of veneer a spray with a activator until all 24 slots have veneers glued in them.

Then cut into washers or rings .

Sorry I don't make many pens, I do enjoy wood working but I make very few pens.

I thought I would share this with you.

You must have a engine style lathe, a indexer and a live tool post cutter that you can cut a 0.030 width of a slot.

Finished product is a billiards chalk holder.

This is made out of Elk antler and Gabon Ebony.

hope this gives a few of you guys some ideas