Do not try this at home!  See, I'm crazy about trying dumb things.

See, I'm crazy about trying dumb things.

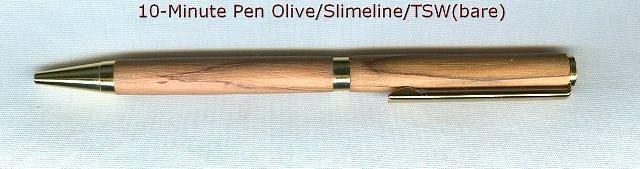

This is a pen I turned just a few minutes ago. From unmarked blank to finished pen was 10 minutes. Now I know I can make a better one, but how bad is it when you can crank one of these babies out in just 10 minutes...from soup-to-nuts? [8D]

Image Insert:

73.16KB

This is a pen I turned just a few minutes ago. From unmarked blank to finished pen was 10 minutes. Now I know I can make a better one, but how bad is it when you can crank one of these babies out in just 10 minutes...from soup-to-nuts? [8D]

Image Insert:

73.16KB