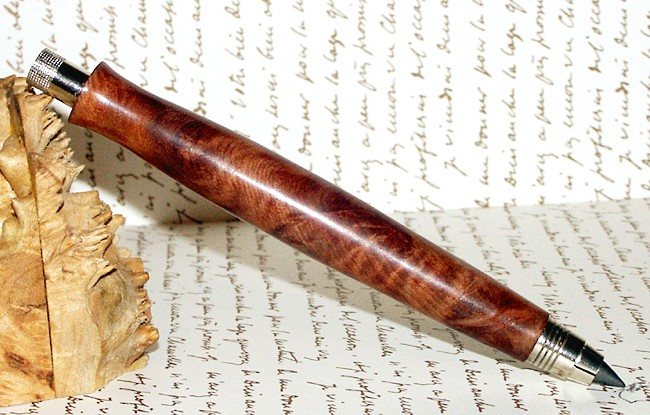

Broke down and bought a couple of the CSU Woodworkers Pencils... other than the PIA drilling them they are real sweet to make... just a freeform shape that you decide on.. I decided on something simple for the first one...

Redwood Burl I had laying around finished with BLO then sanding sealer, CA and TSW... not a bright finish.. more than a semi-gloss, but not quite a gloss..

Of course this is not mine [V]...

Right after I let my 6yr old try it, I lost it forever... "Daddy, this is perfect for me to draw with".. of course I am going to end up spending a fortune on pencil leads now.. [ ]

]

Redwood Burl I had laying around finished with BLO then sanding sealer, CA and TSW... not a bright finish.. more than a semi-gloss, but not quite a gloss..

Of course this is not mine [V]...

Right after I let my 6yr old try it, I lost it forever... "Daddy, this is perfect for me to draw with".. of course I am going to end up spending a fortune on pencil leads now.. [