Constant Laubscher

Member

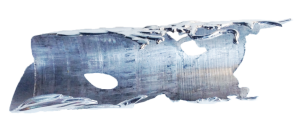

I have done these on a milling machine. It is a 3D Design ( Marine, Navy Seal, and a dragon) When milled it forms sleeve with a 0.5" ID.

This was just a quick try to see if the concept will work and I think it did.

I did not do much to it after it was milled just chrome polish and a light buff.

I did broke a few cutters because I was to impatient and was running the feeds to high.

I was using a 1/16", .04, .03 Ball end mills. I did a .001 step over for the final finish cut.

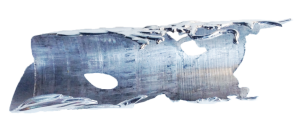

Here you can see the sleeve from the inside

Comments are welcome.

This was just a quick try to see if the concept will work and I think it did.

I did not do much to it after it was milled just chrome polish and a light buff.

I did broke a few cutters because I was to impatient and was running the feeds to high.

I was using a 1/16", .04, .03 Ball end mills. I did a .001 step over for the final finish cut.

Here you can see the sleeve from the inside

Comments are welcome.

Last edited: