Thank you for the comments

Thank you for the comments and I will try and answer your questions.

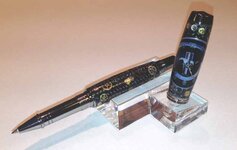

Seamus wrote "So I would love to hear how your casting went, using the alumilite and the "tube-on" style casting. Those pens look great too by the way"

The pour went pretty good, un-eventfull until I de-molded them. 5 out of the 6 tubes had leaked. I thought that I had lost them all, and decided to try and drill the tubes out. As soon as I put some pressure on the plug it popped out, it did that on all 5. The one think that I notice was around some of the parts the CA that I use to glue them on looks like it "cracked". I have not seen that when I used epoxy. But I did use a different CA this time and I am pretty sure it was old. I will try my regular CA (Satellite City) again before I give up on using Alumilite for this application. I liked the way the Alumilite turned pretty easy to cut and polish.

OZturner wrote "

Great pens Mike

Terrific Fit and Finish.

Would love to see them with the caps on.

Brian. "

I'll see if I can get some better pictures tonight.

Lamplight66 wrote "Amazing work! I am very intrigued to know more about doing this style of pen! I've been getting some stuff together. Just would like to know what pen kit you used, and also where you get the carbon fiber!! I've been searching online for about a week, and the I can only find a 500 foot roll!!

That's a little more than I will use ....EVER!! Thanks, Don "

Don this is where I buy my carbon fiber

http://www.sollercomposites.com,carbon fiber,carbon fiber sleeve,Kevlar sleeve, fiberglass sleeves,carbon fiber fabric,epoxy,west system epoxy,nitrile,gloves,nitrile gloves,aramid,fiberglass,kevlar,tape,biaxial tape, biaxial sleeve You can buy it by the foot here. I get the .5" Carbon Fiber Biaxial sleeve. I have tried the colored fiberglass also, and it is okay. Just beaware that the fiberglass is thicker, you have to be very careful about making sure you parts are small and as contored to the tube as you can. It gets real easy to cut into the parts trying to get a good shape on the pen.

Pitoon wrote "very nice! You're pumping those out with ease!"

I wouldn't say pumping them out with ease but it is getting easier for me. You are only seeing the good ones here, you are not seeing the ones I messed up on. The biggest thing that I have found with these is taking your time to get the watch parts as contoured to the tube as possible. If you don't that is where you start cutting into the parts turning. With the small parts you don't have to be as close, but with the big ones you just about have to be dead on.

Mike