Looks great. What did you use for dye? I have been using cactus juice with black alumalite dye and can't get a consistent color throughout my Maple blanks.

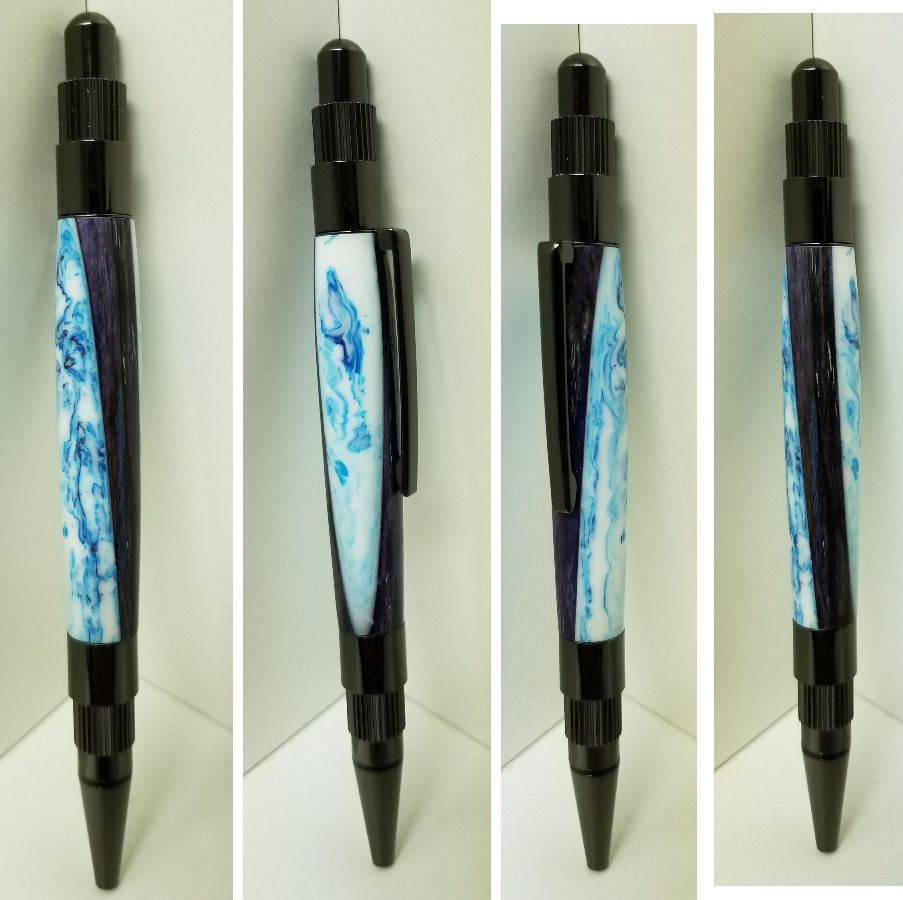

I used CJ with Alumilite Purple dye. However these were spalted (partially rotted) blanks so they accept the dye a lot easier. Maple is a tight grain so if your blanks are not spalting, there may be areas that the dye just can not penetrate well. In this batch of blanks I dyed, there are a couple that have spots where the wood was still good and hard, those spots did not get any dye.

There is also some science behind it all too. Different color dyes have different size particles. I can't remember which colors, but some colors have very large particles and there are some woods that have such a tight grain that these dye particles simply will not fit into the spaces. If I can locate the article again I will post a link. (I might have seen it on Turn Tex web site)

Basically speaking, areas of wood that are very hard, the dye will penetrate less. Try a wood that has consistent grain and see if you have better results. Also note that it takes a lot more dye than you might think to get a good color. The first time I tried to dye purple, the wood came out looking slightly turquoise.

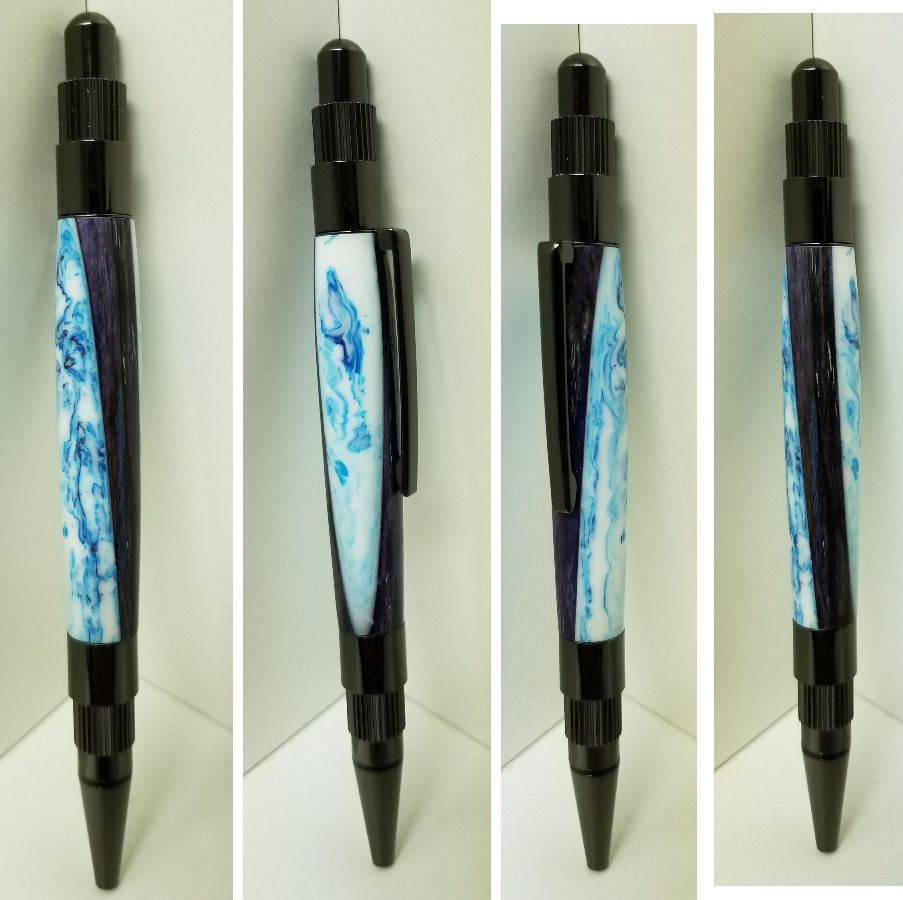

Thanks everyone for the kind responses!