KDM

Member

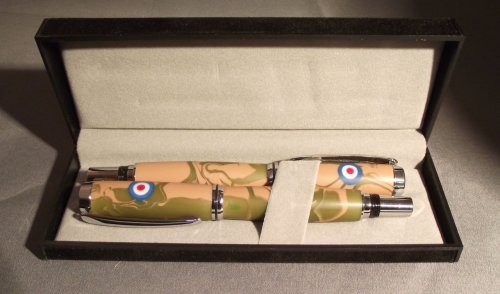

I was asked to make a "airplane themed fountain and rollerball set."

"OKay, couple of airplane clips..." Nope. Anyone know where I can get airplane clips for future reference?

So, I looked up the types of of camo certain aircraft might have had, tried to copy the colour in PR, BING! Airplane camo.

The RAF roundels aren't decals: they're cast in. I drilled holes, filled 'em with blue, drilled, filled with white then drilled and filled with red.

Someone once told me "pens don't have to be glossy." I sort of brushed that off. This is the first time I've made pens and felt the urge for them not to be glosssy!

Yes, I made three blanks in case I fluffed one.

As it happens, I DID fluff one. I'd turned it almost to completion when I dug the tool in and chipped it. I preferred to fill it than start again. See the green and beige blobs? That's the filler. End result looks smart. You'd think it was part of the camo.

Did anyone notice the marks made when the tool was chattering??

"OKay, couple of airplane clips..." Nope. Anyone know where I can get airplane clips for future reference?

So, I looked up the types of of camo certain aircraft might have had, tried to copy the colour in PR, BING! Airplane camo.

The RAF roundels aren't decals: they're cast in. I drilled holes, filled 'em with blue, drilled, filled with white then drilled and filled with red.

Someone once told me "pens don't have to be glossy." I sort of brushed that off. This is the first time I've made pens and felt the urge for them not to be glosssy!

Yes, I made three blanks in case I fluffed one.

As it happens, I DID fluff one. I'd turned it almost to completion when I dug the tool in and chipped it. I preferred to fill it than start again. See the green and beige blobs? That's the filler. End result looks smart. You'd think it was part of the camo.

Did anyone notice the marks made when the tool was chattering??