Mark, Mike (Moke),

Eagle, from long ago, taught me something on delicate segmented blanks. He actually posted it here somewhere but I think most people tended to under use the information while I tended to over do what he said.

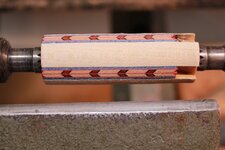

He started off wrapping with thread and CA'ing it. (Gauze works just as well). Then he turned about 1/3 to 1/2 of the length of the blank down about 1/16 inch. Then CAed the fresh turn. then turn the other half; CA again, turn down another 1/16" halfway. CA again, and turn the rest of the way. CA. CA, CA each portion of a turn.

The point is on blanks like this, similar to snakewood, taking a few hours or even days on a delicate blank is worth it. I always worked on other items to break the monotony while waiting on Snakewood, and learned to back off on delicate segments at times when I wanted to "get it done". A none-rushed delicate artistic blank carefully crafted will bring in a few hundred more than an ordinary segment. And Boost your ego to boot! The extra time spent on a delicate blank is worth it. With the experience, one learns when a particular part of the process can be speeded up and which parts to take it easy.

I have never been a very patient person but this more than anything else helped me learn patience, and Eagle started me down this road!