This is #10, if I also count the parts I made to leave in the shop to test fit things.

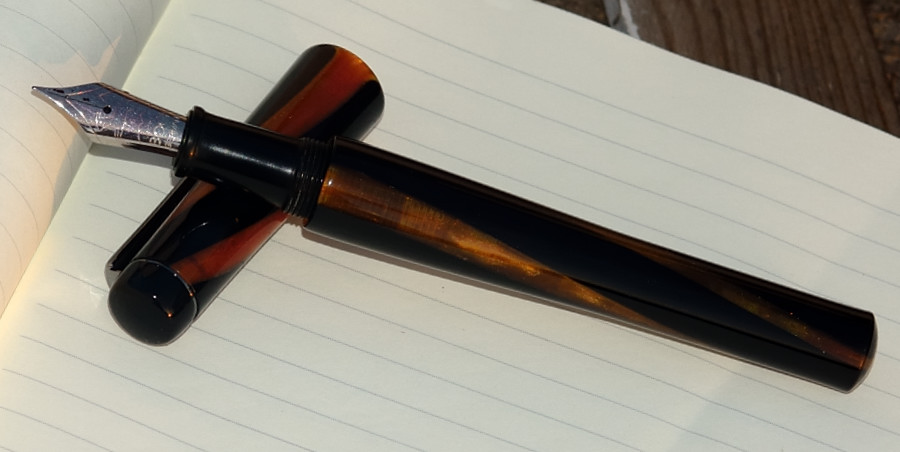

It just came off the lathe, and I haven't even run it through the ultrasonic or soaked the polish crap out of the threads, but I am unreasonably excited about how it came out and wanted to share.

I've been at the scratch-made pens since March, though I haven't been highly productive since I've only made 9 complete pens. Never would have been able to make stuff this nice without the helpful advice of some folks here.

I did this from a Muttblank -- #1, Lava Lamp. It's prettier in person.

Just to show progress, this is #8 (#9 remains unfinished as it is a bulb filler and I decided I wanted to do the end cap differently and had to pour more resin)

#8 and this new one are finally close to the quality I hoped I could do. #8 is my daily carry pen and amazingly comfortable. Both wear #6 Bock nibs and are standard cartridge/converter pens.

It just came off the lathe, and I haven't even run it through the ultrasonic or soaked the polish crap out of the threads, but I am unreasonably excited about how it came out and wanted to share.

I've been at the scratch-made pens since March, though I haven't been highly productive since I've only made 9 complete pens. Never would have been able to make stuff this nice without the helpful advice of some folks here.

I did this from a Muttblank -- #1, Lava Lamp. It's prettier in person.

Just to show progress, this is #8 (#9 remains unfinished as it is a bulb filler and I decided I wanted to do the end cap differently and had to pour more resin)

#8 and this new one are finally close to the quality I hoped I could do. #8 is my daily carry pen and amazingly comfortable. Both wear #6 Bock nibs and are standard cartridge/converter pens.