Test, part - 2

OK, the blanks were taken from the oven this afternoon after 6 runs of 90 minutes at 80° celsius so a 9 hours of oven time. The first thing I did was to weight them and see it was any loss of weight

,

a small loss but a loss, 3gr average from 30 to 27gr so, what was that they lost..???, as they were looking pretty dry at 7%MC right..??? this is what they lost,

6%MC (moisture content). Where that come from...??? environment/air moisture...!

The blank probed was the very same as before and you can see from the indentations I made on the the second time around, the pins were indeed making deep contact,

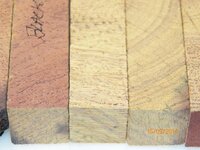

Now, the colour comparison test seem to show that, the roasting of the blanks did not affect the colour, thanks to the foil protection, this is the pic taken of the group after coming out of the oven,

Before I put them in the stabilisation chamber, I took the readings again with the Durometer, why...??? because I knew that, when wood is toasted to almost 0% MC, the wood cells harden slightly, did this happen...??? you be the judge

I have so far, validated every single expected event, as I mention before a few times, the blanks are now under full vacuum, have started at 3:50pm and will be turned off about about midnight, the blanks will stay submerged until tomorrow morning, after of which they will be drained and let drain for the rest of the day, I should cook them sometime tomorrow evening.

The next day I will do a few simple surface colour tests to measure any difference, after that I will select the worse blank of the batch and I will turn it round halfway and then proceed with my normal CA finish, 2 thin + 6 medium + 2 thin, sand, polish it and see what comes up.

The time of turning/completing the sample will be recorded, along with ambient temp. and humidity, this first pic will be taken immediately and shown on this thread, I will use the super Macro function to provide clear details of the finished surface.

The blank will have an identical pic taken every 2 days, while the treated blanks (7) will be returned to Bob immediately. There will be about 1 week before he gets them back, in the mean time he and all of us, we can see the sample every 2 days and look for any signs of cracking, if by the time Bob get his blanks back, the sample performs as I expect it to, Bob will be safe to make is important commissioned pen and any others he may wish to do so...!

My commissioned pen is waiting for the kit to arrive from the USA (PSI), I couldn't find what I wanted on any of the Australian suppliers, not that is something unique, you guys have been using these kits for some time but, the correct plating, wasn't available here.

A simple kit with a couple of spare tubes + shipping AU$70.90

, I better cast something for the tubes that will make it worthwhile otherwise, I will get pretty wild...!

Anyway, we wait and see...!

Cheers

George