Originally posted by Proud_Poppa_of_2

Those are beautiful barrels, Steve. I have no experience whatsoever with antler. Is the material hollow? Does antler give a strong odor when turning? I notice the high gloss on your barrels. How did you achieve that?

Mike,

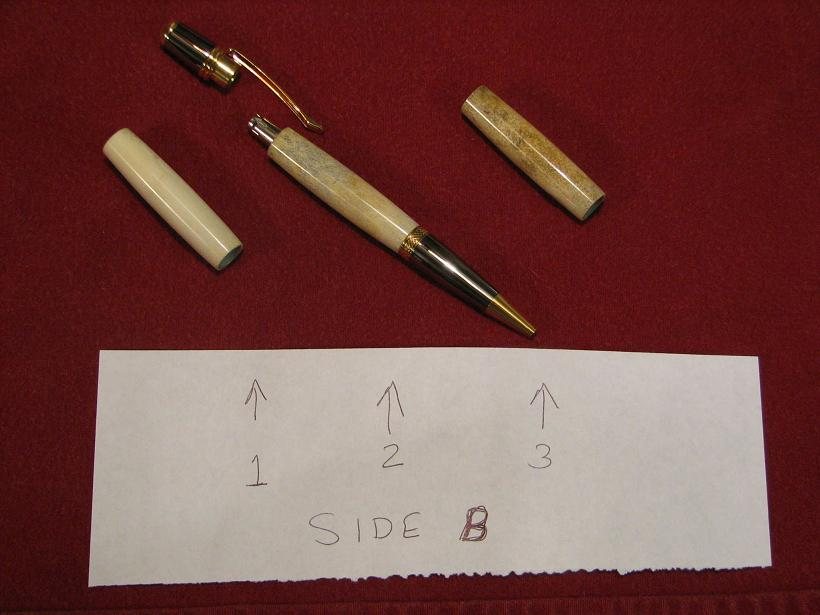

Antler grows like (is, actually), bone. Animals like porcupines and squirrels chew shed antlers to get the calcium they contain. The outer "skin" is hard, like bone and the inner core is marrow, like bone. Generally, the antler base, the outer layer and tips of the antler points are solid bone and they gradually change to marrow, sometimes very porous, as they approach the center of the antler.

While lots of folks complain about the smell of antler, I have used mostly moose antler and some deer and have found the objectionable smell occurs mainly during cutting and drilling. I have just a Sears shop vac with fine fitler and notice very little smell when turning and sanding. It may make a difference how "green" the antler is. I've used primarily antler that has been shed 6 months of more and is fairly dry. I find my own moose sheds using a black lab I trained and use mostly the older, chewed antler to cut blanks from.

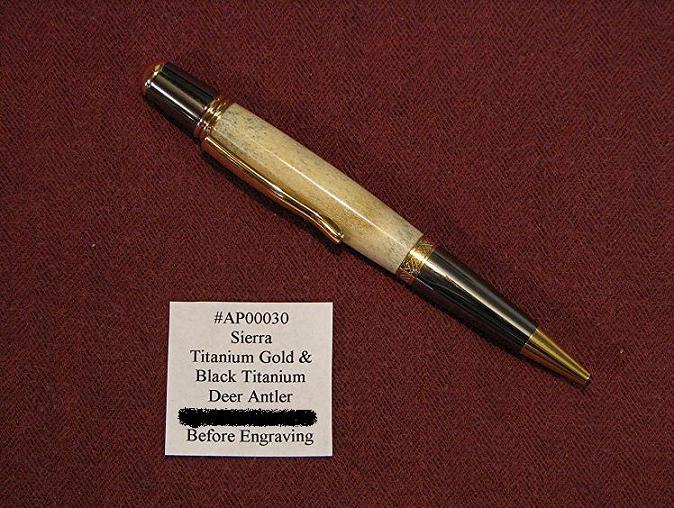

Regarding finish, I am a novice - but learning. As the pen nears final size (maybe 1/16" left to shave) I soak the marrowy areas (if any) with thin CA while hand turning the lathe. Then I let it dry 10-20 minutes to partially stabilize the porous areas. I continue turning to final form. I sand the raw antler with US Grit 220, 320 & 400 (Makita sandpaper that is ivory color, not black). Then I further sand with European Grit 800, 1200 & 1500 (also ivory color- available from Bill at Arizona Silhouette). If you stay off the bushings, the light colored sandpaper will not deposit black spots on the porous antler. Once sanded, I use my shop vac and fingers to suck out the loose sanding grit from the antler (turning slowly by hand on the lathe). As a finish I use 2 coats each of thin, medium & thick CA. If the antler was really porous, I may apply a third coat of the thick CA. I spray accellerator after each coat (except the thin which dries quickly on its own). I then sand with a used piece of 320 grit until the gloss disappears completely. Sand a bit then stop the lathe and check it. You want all glossy spots and lines gone, but do not want to sand the whole finish away. The I sand US 400, European 800, 1200, 1500, and micromesh 2400 through 12000.At about micromesh 4000 you have a decent satin finish. The last three micromesh (6000 through 12000) provide the gloss. I use the micromesh dry, always moving, light pressure and only 10-15 second per barrel per grit. Building up heat will ruin the finish (and the micromesh).