alamocdc

Member

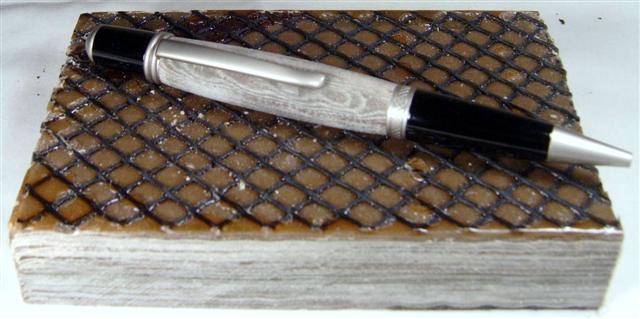

I saturated about 70 pieces of AF issue desert camo material in marine epoxy and pressed them into a custom made wooden mold. FWIW, Skye said it wouldn't look good. When it cured, I cut a piece and turned this Satin Nickel Sierra. As the skew cut through the material I noticed an interesting look and a rather tactile feel so I decided to leave it like that. It was a real pain and I'm not sure I'll do this often, but... The design in the fabric under the clip and on the opposite side is due to the plastic gutter screen that I put on the top and bottom before pressing.

As always, feel free to hammer away. I think I'll give this to the guy that gave me the uniform so we can see how it holds up.

As always, feel free to hammer away. I think I'll give this to the guy that gave me the uniform so we can see how it holds up.