Chuck Key

Member

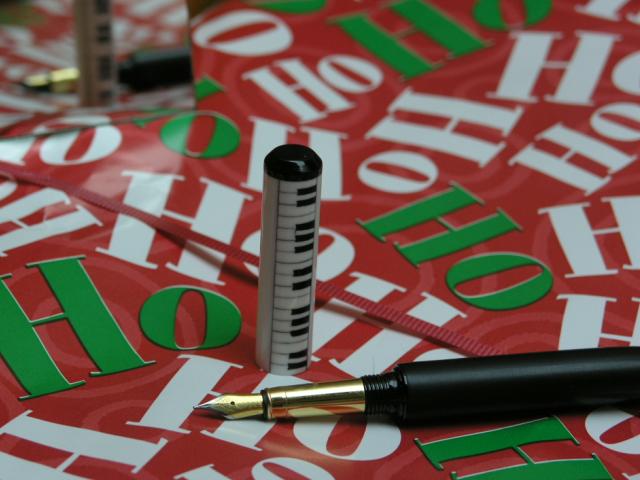

I know, the picture is a little busy but Seasonal, the mirror image is out of focus and it is not wood. Anyway, this is my first attempt at a keyboard glue up.

Chuckie

Chuckie

Originally posted by Deere41h

<br /> If I had to guess it was printed on paper and embedded in PR. Only a guess though.

Originally posted by Deere41h

<br />Very nicely done John....I assume the kit is the Panache. Are you going to share how you did the keyboard? If I had to guess it was printed on paper and embedded in PR. Only a guess though.

That is one very nice pen!!! I really like it.

Originally posted by Ron in Drums PA

<br />Wow! Nice!

Thanks for sharing the info Chuckie.

Did you use the black CA to help delineate the keys?

Originally posted by dfurlano

<br />oh, how did you thread the inside of the cap?

Again, really nice job!

Originally posted by Tea Clipper

<br />Wow, very nice Chuckie - thanks for the instructions too! That looks like a lot of work/effort there, I'm glad it worked out for you (I'd hate to see it blow up into a million pieces![:0]). You must have been sweating bullets turning that thing, huh ?!?

Originally posted by Chuck Key

<br />Yes is Panache and no I did not use a printer or paper. It is 32 pieces glued up with 31 glue joints.

ere is a list of steps I posted at Yahoo Penturners:

Here is a quick list of the steps performed to complete the keyboard. I believe all the materials are listed except the black rubberized CA glue. Do not attempt the glue up using the black rubberized CA on your anniversery when you are planning to go to Ruth Chris for dinner and to a XMAS party that evening. """ Could you explaind I'm short of brain with this comment, Thanks """

4. Glue in black keys cut from .060 sheet Styrene

Chuckie

When you talking about styrene, is a petrol product? we do have it here but is use for tomatoe or brocoli boxes but would melt with CA what kind of styrene you talking about, where do you get black CA? never heard before, Thanks

Originally posted by Chuck Key

<br />Originally posted by Tea Clipper

<br />Wow, very nice Chuckie - thanks for the instructions too! That looks like a lot of work/effort there, I'm glad it worked out for you (I'd hate to see it blow up into a million pieces![:0]). You must have been sweating bullets turning that thing, huh ?!?

Actually, I had the keys glued up for a bottom barrel of the same style. It had 24 keys on it. Messed it up when cutting the slots for the sharps and flats. Just one bad cut will trash the whole barrel.

Didn't sweat any bullets. It was 20 degrees here last evening and my shop could use a much improved heating system in that weather.

Chuckie

Originally posted by Darley

When you talking about styrene, is a petrol product? we do have it here but is use for tomatoe or brocoli boxes but would melt with CA what kind of styrene you talking about, where do you get black CA? never heard before, Thanks