Bits of gold for recycling...

Small hobby induction furnace ... melting the gold directly into the crucible.

The resulting 18k gold ingot.

A slice off the ingot was pressed between stainless steel rollers to produce a thinner sheet...

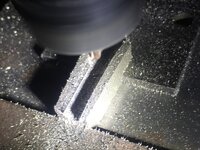

Using a press die cutter to cut away the form of the nib leaves no ragged edges, the remainder can be recycled into the next nib with more scrap gold.

Weight of the nib by itself at 1.12 grams.

A view of 3 nibs nearly completed, with the ingot and several precursor stages in background

Several nearly completed nibs, one of which has been touched by flame and not yet polished up.

Closer look at the 3 newer nibs, before cutting the ink channel and building the point.

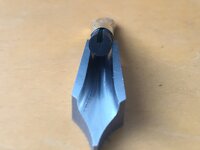

A completed nib, with points on both and the ink channel fully cut on the left one only.

(It looks like the one on the right wasn't quite centered, and thus, didn't make the cut.)

As his setup is made to allow him to recycle all of his materials continually, it is merely a situation where he can freely collect the materials he needs and continue to practice his craft, till the results are as near to perfect as can be had. I envy your workshop!