Ravenbsp

Member

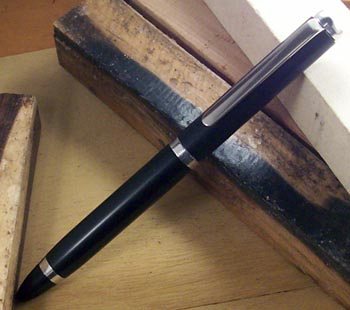

I made this pen from acetal rod stock, also known in DuPont land as Delrin. The bands and final are hand made from aluminum rod, the clip is a left-over from another kit, but seemed to go nicely with this pen.

I made this for an army officer who wanted a pen that would stand-up to just about anything, but not primarily metalic, because he said he would be likely to bend it. I don't even want to think about the abuse its going to get. I've used acetal in other apllications and its very tough, resilent material with a high breaking point. It doesn't really polish to a "glassy' finish, but in his opinion that would have been a negaive anyway.

It has a slimline transmision . The nib has a really nice tolerance. The the ball-point extends and retracts easily with no side-to-side movement when used. Sorry if I'm getting long winded, but it seemed like it took forever to make this one-off prototype and while I think it looks ok, I think that it is a little aesthetically lacking. At any rate, comments are welcome.

I made this for an army officer who wanted a pen that would stand-up to just about anything, but not primarily metalic, because he said he would be likely to bend it. I don't even want to think about the abuse its going to get. I've used acetal in other apllications and its very tough, resilent material with a high breaking point. It doesn't really polish to a "glassy' finish, but in his opinion that would have been a negaive anyway.

It has a slimline transmision . The nib has a really nice tolerance. The the ball-point extends and retracts easily with no side-to-side movement when used. Sorry if I'm getting long winded, but it seemed like it took forever to make this one-off prototype and while I think it looks ok, I think that it is a little aesthetically lacking. At any rate, comments are welcome.