davinci27

Member

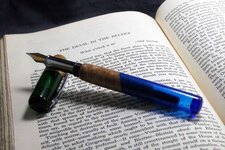

See Through Gift for VisExp

I participated in the pen/puzzle swap over on the eagle forum, and I got paired up with Keith. He sent me an awesome feather pen (http://www.penturners.org/forum/showthread.php?t=42906) and a very beautiful koa and aluminum blank that is currently on my lathe. In return :biggrin: I sent him this pen.

I have to say this pen was alot of fun to make, but the first few tries still lay on the shop floor. The pr came from http://exoticblanks.com of course, and the wood is ribbed fruit malle burl from scribblesticks. the kit parts are out of a Barron/Navigator. It's hard to see in some of the pictures, but the burl continues up into the upper and lower tubes. I've included a close up where you can see the grain.

I'll post the blank I got from keith as soon as it is turned into a pen :wink:

As alway comments/critiques/criticisims are welcomed.

I participated in the pen/puzzle swap over on the eagle forum, and I got paired up with Keith. He sent me an awesome feather pen (http://www.penturners.org/forum/showthread.php?t=42906) and a very beautiful koa and aluminum blank that is currently on my lathe. In return :biggrin: I sent him this pen.

I have to say this pen was alot of fun to make, but the first few tries still lay on the shop floor. The pr came from http://exoticblanks.com of course, and the wood is ribbed fruit malle burl from scribblesticks. the kit parts are out of a Barron/Navigator. It's hard to see in some of the pictures, but the burl continues up into the upper and lower tubes. I've included a close up where you can see the grain.

I'll post the blank I got from keith as soon as it is turned into a pen :wink:

As alway comments/critiques/criticisims are welcomed.

Attachments

Last edited: