thewishman

Member

Wanted to show off a couple more metal pens. Using 1/2" stock for a Sierra means only about .026" of material has to be removed. These metals, and the aluminum were easy to barrel trim with a HHS trimmer, and they turned fine with HHS. I use carbide and that works well, too.

I tried polishing to a bright, reflective surface, but I couldn't get a good picture, and bright and shiny was boring to me. The copper was polished through the MM grits, then I took down the shine with maroon Scotch-brite (https://mt-rsr.com/products/scotch-...Vr1dqm_send3K6cvHXJFscm0WDVa6d6RoCVr0QAvD_BwE). I moved the pad slowly from the headstock out, then back the opposite way - it made a nice crosshatch pattern, but I can get a good picture of it, either.

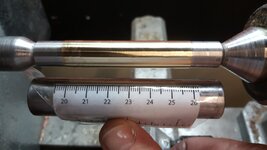

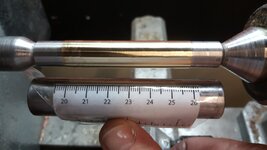

The brass turned really well, and I wanted to do something different. Got it down to size and then sanded lengthwise with 220 grit Norton 3X to make an even texture. Then I wanted to cut bright lines in a nice pattern, so I printed a ruler (printable-ruler.net) and taped the metric side to my tool post. Used the corner of my carbide tool to cut into the brass at 5mm intervals. Again, I used a "design opportunity" to make a couple of lines a bit different (okay, so I messed up a couple of lines) and it looks good to me.

I tried polishing to a bright, reflective surface, but I couldn't get a good picture, and bright and shiny was boring to me. The copper was polished through the MM grits, then I took down the shine with maroon Scotch-brite (https://mt-rsr.com/products/scotch-...Vr1dqm_send3K6cvHXJFscm0WDVa6d6RoCVr0QAvD_BwE). I moved the pad slowly from the headstock out, then back the opposite way - it made a nice crosshatch pattern, but I can get a good picture of it, either.

The brass turned really well, and I wanted to do something different. Got it down to size and then sanded lengthwise with 220 grit Norton 3X to make an even texture. Then I wanted to cut bright lines in a nice pattern, so I printed a ruler (printable-ruler.net) and taped the metric side to my tool post. Used the corner of my carbide tool to cut into the brass at 5mm intervals. Again, I used a "design opportunity" to make a couple of lines a bit different (okay, so I messed up a couple of lines) and it looks good to me.