Travlr7

Member

This past week I worked Security for a production of The Nutcracker. One of the women helping backstage and got talking about pens, etc. She worked at Quality Hardwoods, a local mill and hardwood dealer. She told me that they were having a sale last Sat & Sun (50% off).

I went down to their mill and cleaned out their Scrap box of walnut, cherry, Box Elder, Sasafrass, Oak, Beachnut, Curly Maple, Soft Maple, and several items I haven't identified yet. I figure that even at the prices marked on them, I got about $100.00 value of "shorts". The bill was for 7.00 less 50%, so I guess this is a $3.50 gloat.

When I went to work Sunday, there was a piece of Boxelder waiting for me that was big enough for about 16 pens.

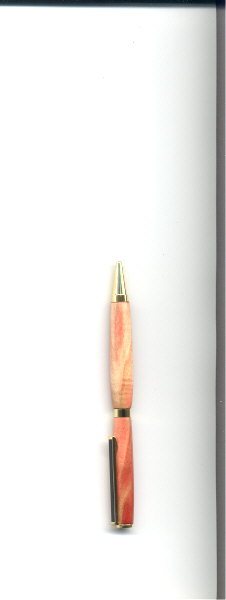

So, I said to myself ................. Self...That lady deserves something in return. I usually make something out of gifted wood to give back to the giftor.

In this case, it's a pen. Hope she likes it.

The Boxelder turned very rough.... a lot of tearout. I didn't realize until I was done and finishing it that I had changed lathe speed to do a bowl and was only going at 1250 rpms. I usually turn pens at full speed of almost 4000. I hope that was the reason for the tearout, or I'll have to charge more for these. Final "tool" used was 60 grit gouge, 100 grit, 150 grit, Parifin oil rubbed with the back of a round skew (Tip from Rich), 320, 400, 600 grits. Finish is 8 coats of French Polish and Two of Briwax.

Thanks for looking,

Bruce

I went down to their mill and cleaned out their Scrap box of walnut, cherry, Box Elder, Sasafrass, Oak, Beachnut, Curly Maple, Soft Maple, and several items I haven't identified yet. I figure that even at the prices marked on them, I got about $100.00 value of "shorts". The bill was for 7.00 less 50%, so I guess this is a $3.50 gloat.

When I went to work Sunday, there was a piece of Boxelder waiting for me that was big enough for about 16 pens.

So, I said to myself ................. Self...That lady deserves something in return. I usually make something out of gifted wood to give back to the giftor.

In this case, it's a pen. Hope she likes it.

The Boxelder turned very rough.... a lot of tearout. I didn't realize until I was done and finishing it that I had changed lathe speed to do a bowl and was only going at 1250 rpms. I usually turn pens at full speed of almost 4000. I hope that was the reason for the tearout, or I'll have to charge more for these. Final "tool" used was 60 grit gouge, 100 grit, 150 grit, Parifin oil rubbed with the back of a round skew (Tip from Rich), 320, 400, 600 grits. Finish is 8 coats of French Polish and Two of Briwax.

Thanks for looking,

Bruce