BradG

Member

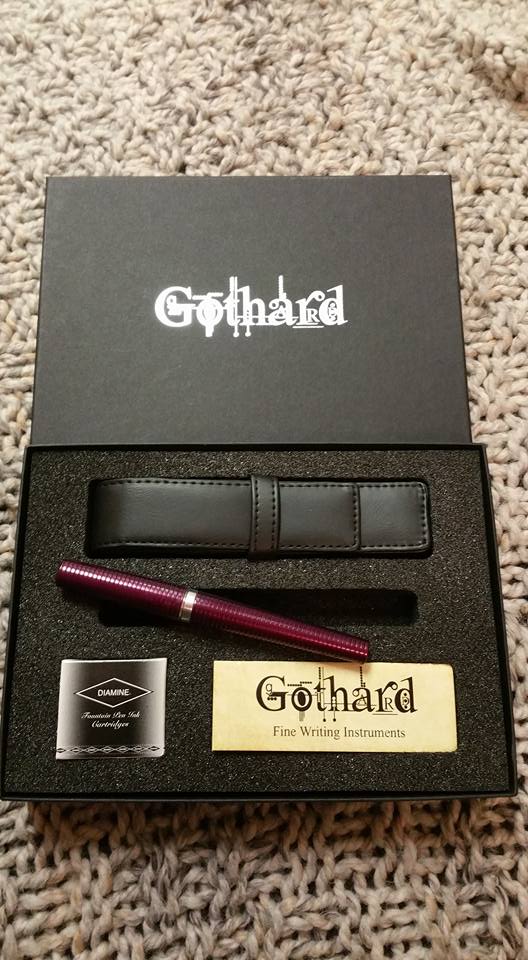

Handmade with aircraft grade aluminium, and anodised purple, featuring a German JoWo Nib

Will be half a dozen colour variations of the same pen over the next few days, so il just post them as replies on this thread rather than creating a new post for each one.

Will be half a dozen colour variations of the same pen over the next few days, so il just post them as replies on this thread rather than creating a new post for each one.