A few weeks ago, Jim Zorn posted a few pens and pictures of his home-made 2 axis CNC pen lathe. You can see the post here:

http://www.penturners.org/forum/f13/new-pen-lathe-155359/

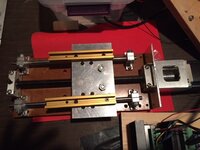

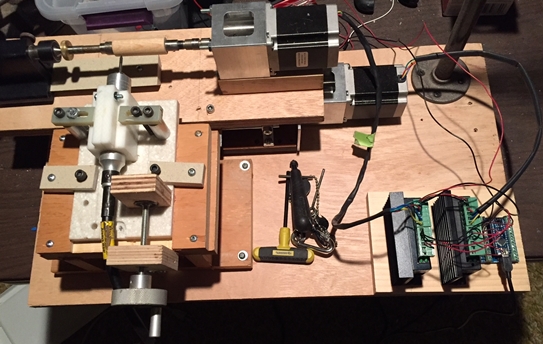

Jim did a demo of this for our Penturners club and was scheduled for a repeat at the Richmond Woodturners club meeting in July. His vacation is interfering with that so I threw together some spare parts and came up with a version a little different but functionally the same to fill in for him. These run on an Arduino with free software. All you need is some simple GCode commands and these machines can do anything a Beall Pen Wizard does and more for a fraction of the cost.

Gisi style pens and Celtic knot are carved and filled with polymer clay. Cross hatch and faceted cap are just carved and finished.

http://www.penturners.org/forum/f13/new-pen-lathe-155359/

Jim did a demo of this for our Penturners club and was scheduled for a repeat at the Richmond Woodturners club meeting in July. His vacation is interfering with that so I threw together some spare parts and came up with a version a little different but functionally the same to fill in for him. These run on an Arduino with free software. All you need is some simple GCode commands and these machines can do anything a Beall Pen Wizard does and more for a fraction of the cost.

Gisi style pens and Celtic knot are carved and filled with polymer clay. Cross hatch and faceted cap are just carved and finished.